Light Metal Wire Mesh Braiding Machine

Function introduction: light metal wire mesh machine, suitable for metal wire mesh weaving industry, can weave hole mesh, dense grain mesh and other non-metal mesh. Its weaving products are widely used in petroleum, chemical, machinery, aviation and other industries. The main features include: 1. Strong adaptability to metal wires. 2. Large adjustment range. The lines are diverse, such as plain weave, oblique weave, Zhuzi weave, and conical contrast dense grain mesh. 3. Using shuttleless linear weft insertion, mechanical automatic warp feeding and coiling, small opening, flat net surface, less net disease. 4. With warp, weft, automatic parking and display function. 5. The whole machine has low center of gravity and low noise. Specifications and technical parameters: TYPE model ZWJ-1300BZWJ-1600BZWJ-2100BMESHSIZE mesh surface density 40-400mesh/inch40-400mesh/inch40-400mesh/inchWIREDIAMETER wire diameter range 0.025-200mm 0.025-0.200mm 0.025-0.200mmBEATING-UPFREQUENCY beating-up times 70r/min70r/min70r/minMESHWIDTH weaving mesh width motor power shape dimensions (length x width x height) 2.6m * 2.8m * 1.4 m2.6m * 3.1m * 1.4 m2.6m * 3.6m * 1.4m support customization

Non-lubricated wire weaving machine

Function introduction: ZWJ1300B1 to improve the model. This improvement mainly involves lubrication and speed increase. The lubrication improvement is based on the current situation that users have serious on-site lubrication and refueling workload, serious on-site oil pollution, and the current national environmental protection form is unprecedentedly severe. In order to improve the above situation, this improvement mainly reduces lubrication points, adopts bearings, I .e. no lubrication mechanism, and speed increase the working efficiency of organic type 70 times per minute, under the condition that the model structure remains unchanged, some parts are changed through design, and the speed is increased to 120 times per minute, which greatly improves the production efficiency and reduces the labor cost. Specifications and technical parameters: TYPE model ZWJ-1300B1ZWJ-1600B1ZWJ-2100B1MESHSIZE mesh surface density 40-400mesh/inch40-400mesh/inch40-400mesh/inchWIREDIAMETER wire diameter range 0.025-200mm 0.025-0.200mm 0.025-0.200mmBEATING-UPFREQUENCY beating-up times 70-120r/min70-120/min70-120r/minMESHWIDTH mesh width motor power shape size (length x width x height) 2.6m * 2.8m * 1.4m 2.6m * 3.1m * 1.4m 2.6m * 3.6m * 1.4m model supports customization of various special requirements

CNC Gold Steel Mesh Braiding Machine

Brand Jinglian processing customization is the overall size of 4500*3300*2200 weight 12t type molding machine alias mesh weaving machine motor power 5.5kw color green use weaving diamond mesh CNC diamond mesh weaving machine can realize one machine weaving a variety of mesh crimped net, first the warp silk rolling, then the diameter, and then fully automatic weaving. This type of mechanical warp and weft wire error automatic shutdown alarm, micro-electric numerical control control, simple operation, energy saving, time saving, labor saving, changing the mold can be carried out various mesh diamond net weaving. Diamond net is a new type of high-end household profile on the market, suitable for assembly in the relatively new high-end doors and windows, to meet the needs of high-end customers. It not only has the effect of insect prevention and theft prevention, but also achieves the effect of aesthetics. The state of the net is iron plate-shaped, hard, and the impact resistance is super strong, which is the most significant feature of our products. Light transmission is very good, from the inside to the outside to see high clarity, from the outside to the inside to see blurred, can create a safe and comfortable private space for you, at the same time can block mosquitoes into the room, is the room and office space warm, safe, anti-theft, bulletproof products. 1. Product application: Diamond net anti-theft screen window is made of high-strength stainless steel wire diameter heavy-duty precision loom. The surface is sprayed and matt, and is concealed on aluminum doors and windows. It is organically compounded into one body. It has high strength, simplicity and strength, shear resistance, impact resistance and other high-quality properties, and truly embodies the advantages of anti-theft, insect prevention, ventilation, beauty, safety and the like. 2. Main Uses: The diamond net produced by the full-automatic diamond net weaving machine is widely used in balconies and windows of high-grade residential areas such as residential unit buildings, villas and garden houses. Office doors and windows of office buildings, office buildings and enterprises and institutions; Residential buildings with stainless steel anti-theft nets and stainless steel gate cannot be installed; Customers who like simple and generous window decoration but also have anti-theft, fire prevention and mosquito prevention functions.

Gold steel mesh weaving machine

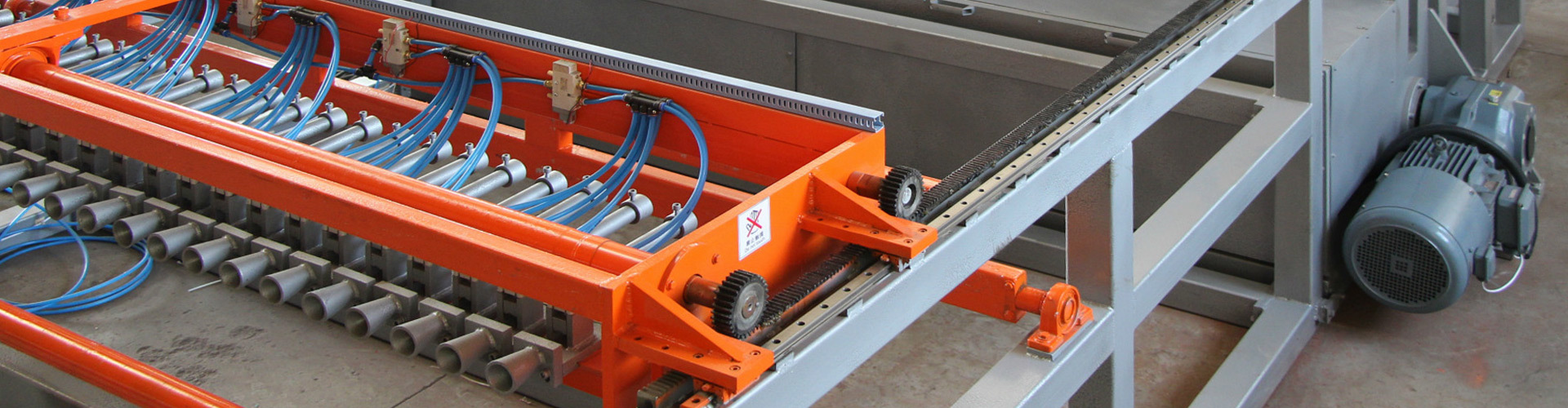

Customized processing is the brand Jinglian type braiding machine alias silk screen braiding machine, stainless steel braiding machine motor power 5.5(kw) overall dimensions 2600mm × long × 3000mm × wide × 2000mm(mm) high weight 4.8(t) specification JL-1600D braiding hole range 4-20 mesh JL-1600D new mesh loom this machine is manufactured by our company with the introduction of international advanced technology, can replace similar imported products, using flexible rapier linear weft, secondary weft insertion, mechanical intermittent automatic feeding diameter, active rolling net, tread plate hanging heft, diameter and weft broken wire automatic shutdown. It has the advantages of large weft beating force, strong bearing capacity, high precision and smooth mesh surface. The products are widely used in: construction, petroleum, chemical, daily necessities and other fields. The machine is improved on the basis of the original 1300D, absorbing the advantages of heavy-duty weaving machine, with the characteristics of strong and durable heavy-duty weaving machine, and 130D machine fast flexibility. Technical parameters: 1. main features: the use of four heddle hanging heddle way, diverse lines, bear the tension. 2. braided pore range: 4-20 mesh 3. braided maximum wire diameter: 1.0mm 4. crankshaft speed: 40 times/min 5. power 5.5KW 6. external dimensions: 2600mm long × 3000mm wide × 2000mm high 7. machine weight: 4.8T 8. warp and weft wire failure automatic parking alarm function. Main technical parameters of wire mesh machine model JL1600D mesh surface density 4-20 mesh crankshaft speed 40r/min motor YEJ100L2-4 power supply 50HZ 380HZ three-phase four-wire color green certification IATF16949:2006 mesh machine photo

ZWJ--1300 hanging heddle type wire mesh machine

Overview: Suitable for metal wire mesh weaving industry, can be prepared empty mesh, dense grain mesh and other non-metal mesh. Its preparation products are widely used in petroleum, chemical, machinery, aviation and other industries. Reliable use, simple operation, reduced raw materials, good quality and high production efficiency. Main features: 1 strong adaptability to metal wire; 2 large adjustment range. There are various lines, such as plain weave, oblique weave, Zhu Zi weave and conical contrast dense weave net. 3. It adopts shuttleless linear weft insertion, mechanical automatic warp feeding and roll taking, with small opening, smooth net surface and less net disease. 4 It has the functions of warp breaking, weft breaking, automatic parking and display; 5 The whole machine has low center of gravity and low noise. Technical parameters: model: mechanical, fully automatic, semi-automatic speed: 70 times/min maximum mesh width: 1300/1600/1800/2600mm wire diameter: 0.01-0.45mm mesh density 20-130 mesh color green warranty period: 1 year certification: IATF16949:2016 delivery photos:

Stainless steel mesh weaving machine

Overview: Suitable for metal wire mesh weaving industry, can be prepared empty mesh, dense grain mesh and other non-metal mesh. Its preparation products are widely used in petroleum, chemical, machinery, aviation and other industries. Reliable use, simple operation, reduced raw materials, good quality and high production efficiency. Main features: 1 strong adaptability to metal wire. 2 large adjustment range. There are various lines, such as plain weave, oblique weave, Zhuzi weave, cone contrast dense grain network. 3 It adopts shuttleless linear weft insertion, mechanical automatic warp feeding and roll taking, small opening, flat net surface and less net disease. 4 It has the functions of warp breaking, weft breaking, automatic parking and display. 5 low center of gravity, low noise.

Full-automatic shuttleless net weaving machine

The company was founded in 1972 and has been engaged in the machinery manufacturing industry for more than 40 years. It now covers an area of 42000 square meters and a construction area of 19335 square meters. The total annual output value is more than 21000 million yuan. The main production equipment 453 sets (sets), the main testing equipment 72 sets (sets). Manufacturing mainly covers: heat treatment, machine, welding, assembly and other processes. At present, the main products are: tractor brake pull rods, construction machinery parts, wire mesh weaving machines, compaction pavers, automobile gearbox reduction wheels, shuttleless mesh looms, flanges, agricultural machinery parts, metal wire weaving machines, metal wire mesh Loom, automobile transmission parts, tractor parts, railway parts, compaction paver parts and other products. Now it has become an excellent supplier of well-known enterprises in China, such as Beijing BorgWarner transmission Co., Ltd., John Deere (Tianjin) Co., Ltd., Dana Park (China) compaction and paving equipment Co., Ltd., Taiyuan Jingfeng Railway Electrical Equipment Co., Ltd. In 2005, it independently developed and manufactured the "metal wire mesh loom". In 2012 and 2018, it obtained two new utility patents respectively. The products were sold to Shanghai, Zhejiang, Hebei, and exported to India and other places.

Overview Origin: Hebei Raoyang Brand: Jinglian Name: Metal Wire Mesh Loom Color: Green or Customer Requirements Certification: IATF16949:2006 After Sales: 7*24 Hours Telephone Response ZWJ-1300D Loom is a new model formed by improving some parts according to customer requirements on the basis of ZWJ-1300B Loom. Compared with B type machine, D type machine has greatly improved rigidity and is therefore more suitable for weaving fabrics with larger wire diameter. Overview: Suitable for metal wire mesh weaving industry, can be prepared empty mesh, dense grain mesh and other non-metal mesh. Its preparation products are widely used in petroleum, chemical, machinery, aviation and other industries. Reliable use, simple operation, reduced raw materials, good quality and high production efficiency. Main features: 1 strong adaptability to metal wire; 2 large adjustment range. There are various lines, such as plain weave, oblique weave, Zhu Zi weave and conical contrast dense weave net. 3. It adopts shuttleless linear weft insertion, mechanical automatic warp feeding and roll taking, with small opening, smooth net surface and less net disease. 4 It has the functions of warp breaking, weft breaking, automatic parking and display; 5 The whole machine has low center of gravity and low noise. Main technical parameters: overall dimensions: length x width x = 3010mm x 2860mm x 1420mm, overall weight: 3650kg, mesh density: 20~140# maximum amplitude: 1300mm crankshaft speed: 72rpm heald frame quantity: 2,4 motors: YEJ100L2-4 power supply: 50HZ 380V three-phase four-wire main technical parameters model ZWJ--1300D dimensions (length x width x height) 3010mm x 2860mm x 1420mm overall weight 3650Kg maximum width 1300mm crankshaft speed 72rpm heald frame number 2,4 motor YEJ100L2--4 power supply 50HZ 380V three-phase four-wire mesh area density 20~140 mesh

Function introduction: diamond net (stainless steel net) weaving machine is manufactured by our company with international advanced technology, which can replace similar imported products. it adopts flexible rapier linear weft insertion, secondary weft insertion, mechanical intermittent automatic diameter feeding, active net rolling, tread plate lifting, and automatic shutdown of warp and weft wire breakage. It has the advantages of large weft beating force, strong bearing capacity, high precision and smooth mesh surface. Specifications and technical parameters: TYPE JL1600D-3J/ZJL2200D-3J/ZJL2500D-3J/ZMESHSIZE mesh surface density 4-20mesh/inch4-20mesh/inch4-20mesh/inchWIREDIAMETER wire diameter range 0.40-1.00 mm0.40-1.00 mm0.40-1.00mmBEATING-UPFREQUENCY weft beating times 40r/min40r/min40r/minMESHWIDTH weave width 1600mm2200mm2500mmMOmmTORPOWER motor power size (length x width x height) special shape 3.0m * 3.6m * 2.2m * 3.0m support 4.2 required Model

The vibration component is driven by the eccentric circle to realize the rapid vibration of the hammer bar up and down to tamp the road surface; Features: It is a high-precision, high-strength shaft part with eccentric circle. The shaft has coaxial mounting circle (used for mounting bearings, oil seals, mounting to mounting seats, etc.) and eccentric circle. The requirements for items such as excircle roundness, cylindricity, size, roughness, eccentric circle position, etc. are very high. Process requirements: the blank is generally made of steel bars or forgings, the main processes include: roughing-heat treatment-semi-finishing-grinding and other processes; the main processing equipment is CNC lathe, CNC cylindrical grinder, quenching equipment and other equipment. Key testing items: surface roughness, roundness, cylindricity, coaxiality, hardness, metallographic and other items; Key testing equipment: large and medium-sized precision coordinate measuring machines, hardness testers, metallographic microscopes and other high-precision testing equipment.

Flange (flange), also known as flange, flange disc, spline flange. Our company can be customized according to customer needs. Flange is referred to as flange, which is just a general term. It usually refers to opening several fixed holes on the periphery of a disc-like metal body to connect other things. This type of product is widely used in machinery, so it looks strange. As long as it is called flange, its name comes from English flange. The parts that connect tubes to each other. Attach to tube end. There are holes on the flange, which can be threaded with bolts to make the two flanges tightly connected. The flanges are sealed with gaskets. Flanged pipe fitting (flanged pipe fittings) means a pipe fitting with a flange (flange or hub). It can be made by casting, or by screwing or welding. Flange joint consists of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the sealing surfaces of the two flanges. After the nut is tightened, the specific pressure on the surface of the gasket will be deformed after reaching a certain value, and the uneven parts on the sealing surface will be filled up to make the connection tight and leak-free. Some pipe fittings and equipment have their own flanges, which are also flange connections. Flange connection is an important connection mode in pipeline construction. The flange connection is easy to use and can withstand greater pressure. In the industrial pipeline, the use of flange connection is very extensive. In the family, the pipe diameter is small, and is low pressure, can not see the flange connection. If in a boiler room or production site, there are flanged pipes and equipment everywhere. In layman's terms, the role of the flange is to make the pipe connection fixed and sealed.

Flange (flange), also known as flange, flange disc, spline flange. Our company can be customized according to customer needs. Flange is referred to as flange, which is just a general term. It usually refers to opening several fixed holes on the periphery of a disc-like metal body to connect other things. This type of product is widely used in machinery, so it looks strange. As long as it is called flange, its name comes from English flange. The parts that connect tubes to each other. Attach to tube end. There are holes on the flange, which can be threaded with bolts to make the two flanges tightly connected. The flanges are sealed with gaskets. Flanged pipe fitting (flanged pipe fittings) means a pipe fitting with a flange (flange or hub). It can be made by casting, or by screwing or welding. Flange joint consists of a pair of flanges, a gasket and a number of bolts and nuts. The gasket is placed between the sealing surfaces of the two flanges. After the nut is tightened, the specific pressure on the surface of the gasket will be deformed after reaching a certain value, and the uneven parts on the sealing surface will be filled up to make the connection tight and leak-free. Some pipe fittings and equipment have their own flanges, which are also flange connections. Flange connection is an important connection mode in pipeline construction. The flange connection is easy to use and can withstand greater pressure. In the industrial pipeline, the use of flange connection is very extensive. In the family, the pipe diameter is small, and is low pressure, can not see the flange connection. If in a boiler room or production site, there are flanged pipes and equipment everywhere. In layman's terms, the role of the flange is to make the pipe connection fixed and sealed.